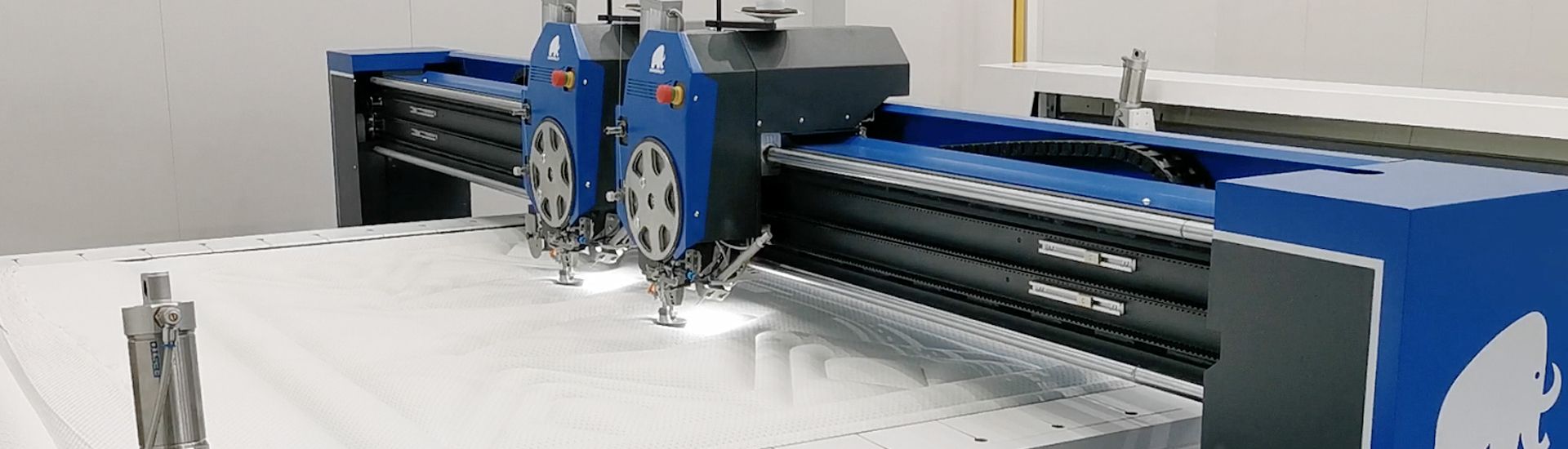

When high precision of sewing patterns as well as heavy and high density materials are needed for the production of mattress panels the Single-Needle Quilting Machine Mammut P2A/P1A is the first choice. All advantages of a Single-Needle Quilting Machine combined with an automatically infeed of material guarantee highest flexibility with consistent efficiency. An asymmetrical drive system of the two sewing heads as well as a marking device for precise cutting between two mattress panels, are only some of the highlights of continued development. For a more detailed overview, please review our literature in the Download area or contact us, as we are always there for you.

Mammut P2A/P1A

Single-Needle Quilting Machine

Productivity

High production quality combined with a low level of machine downtime.

Durability

Robustly designed, extremely durable and ready to use during intense 3-shift factory production.

Characteristics

Sewing foot height electronically adjustable for consistent sewing precision during constant changes of bulk material.

Especially large needle stroke of 53 mm instead of the standard 40 mm allowing sewing without wrinkles of elastic or extremely thick materials.

Presser foot pause manoeuvre allows for pin-point accuracy with thinner needles.

A second variable use sewing head is available for even shorter quilting times. This way two pieces of fabric can be processed in parallel or one piece can be processed with two sewing heads simultaneously.

Extra-large bobbin capacity; Optional automatic bobbin changer.

Technical informations

Technical Data: P1A/ P2A 240

Max. sewing area: 2.400mm x 2.600mm/ 3.600mm

Sewing speed: max. 3.100 st/min

Videos